Similarly to our last update in 2024, progress on D5705 has remained slow due to the current focus for the dedicated team of volunteers being on D8233. Work has however continued to progress which has been set out below and split into sections for ease of understanding. A quick update below shows what parts of the loco have actually had work on them.

North end cab – The drivers and 2nd man seats are in various states of poor condition. The seats have been stripped down, removing the padded seat area and freeing off the seized mechanisms. The metal work is then cleaned up and they are given a fresh coat of paint. We have managed to do a colour match on one of the seats, it’s a lovely shade of brown which will go well with the red leather seats

Engine room (minus engine) and roof - Over the 2025 easter weekend the ELR allowed us access to the overhead crane and each roof panel was removed, the bolt holes were tapped out and the hinges were fitted. Also, at the same time the locking bolts inside the roof panels were unseized. They hadn’t been moved for decades so after lots of heat was applied they were removed, the threads were cleaned up, copper grease applied and these were refitted. At the same time we also removed the fan motor from the loco. The reason for this was the cables inside the motor would not reach the terminals in the terminal box. The covers from the motor were removed and it was discovered that one of the cables was not long enough.

Two engine room roof doors removed with hinges fitted, bolts cleaned up and replaced where necessary and refit to the engine.

Electrical cubicle – 99% complete. One of a couple of jobs that has been outstanding for a while is a couple of the terminal bars in the cubicle required having bridging pieces made and fitted, this is because the terminals on the bars are in pairs.

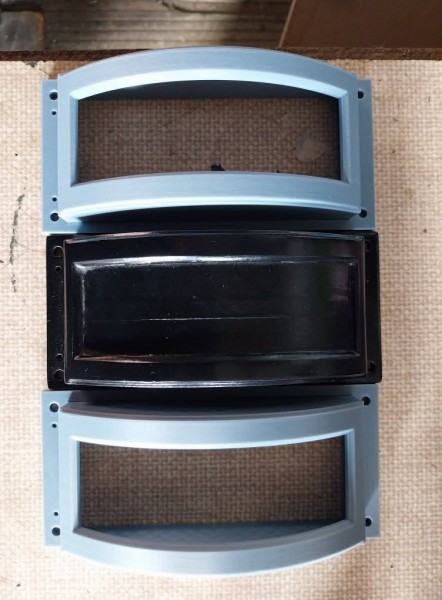

Electrical cubicle/cab desk - Some of the electrical gauges that sit in the drivers desk and also on the side of the electrical cubicle are being overhauled off site by some friends of the project. The ammeters and voltmeter have a curved front and glass similar to some AC electrics, one of them had the cover missing and so we asked one of our newer members if he could 3D print one. This will now be fitted to the relevant gauge once the overhaul of the item and testing has been completed.

Engine - On 8th December 2021, the Crossley HSTVEE8 was sent off to Gen Elec located in Louth, Lincolnshire for restoration. Work has now begun on the restoration and they have now provided an update on the progress of the work as well as providing a list of what remains to be completed.

Work that has been completed on the engine so far include: Bedplate has been pre-cleaned (very dirty, thick black sludge), Main bearing caps fitted and pockets calibrated, Original bearings fitted and bearing nips checked for straightness and Crankcase cleaned and inspected.

Items to be completed include All journals and pins in a serviceable condition except number 5 main (thrust) journal which is damaged and will require machining/grinding. Approximately 25 thousandths of an inch needs to be removed; All main bearings will be re-metalled with white-metal and machined; Fit crank in new bearings with engineers blue and bed crank by hand scraping and Check running clearance as per manufacturers data.

If you are interested in helping out please contact Rob Mason |